Ⅰ. Introduction to Casters

What Are Casters?

A caster is a wheeled device typically mounted to the bottom of objects to enable easier movement. Essential in various applications, casters range from small furniture wheels to large industrial models designed to support heavy loads.

The Development History of Casters

The history of casters stretches back several centuries, evolving with advancements in technology and materials. Originally, casters were simple wooden wheels or metal rollers. However, as industries developed, the need for more sophisticated and durable casters grew. The Industrial Revolution marked a significant shift, introducing cast iron and rubber wheels, offering better durability and floor protection. In the 20th century, with the advent of plastics and synthetic materials, casters diversified further, leading to the development of a wide range of types suited to various applications.

The Role of Casters in Industry

Casters play a crucial role in numerous industries by enhancing mobility and efficiency. In the healthcare sector, casters are used in hospital beds, medical equipment, and trolleys, contributing to patient care and staff efficiency. In retail and hospitality, they are found on shopping carts, luggage trolleys, and furniture, making handling and transportation easier. Casters also play a significant role in office environments, integrated into chairs and movable furniture, enhancing workspace flexibility.

Casters have become an indispensable component in many sectors, providing mobility solutions that are crucial for operational efficiency and ergonomic benefits. This versatility makes understanding the various types of casters and their specific applications essential for businesses and consumers alike.

Ⅱ. Caster Wheel Types

Understanding the different types of casters is essential for selecting the right one for your needs. Casters can be classified based on various criteria, such as wheel surface material, carrying capacity, mount method, caster bracket type, and main usage scenarios.

1. Classification by Caster Wheel Material

Selecting the right wheel surface material is crucial for caster performance. Different materials cater to varying load capacities, floor types, and environmental conditions. Here’s an enriched look at the common materials used in caster wheels:

PU (Polyurethane)

- Özellikler: Combines the resilience of rubber with the toughness of metal. Offers excellent floor protection and noise reduction.

- Applications: Ideal for use in hospitals, laboratories, and retail environments where floor protection and reduced noise are priorities.

- Avantajları: Resistant to many chemicals, solvents, and oils. Provides good grip and is non-marking.

Naylon

- Özellikler: Lightweight yet strong, with high impact resistance.

- Applications: Suitable for both indoor and outdoor applications, particularly where moisture and chemical resistance are needed.

- Avantajları: Highly durable, easy to clean, and resistant to wear, abrasion, and many chemicals.

Lastik

- Özellikler: Offers cushioning and shock absorption, making it gentle on floors.

- Applications: Commonly used in environments requiring quiet operation, such as libraries and hospitals.

- Avantajları: Provides excellent grip and traction, minimizing slip risks on wet or slippery surfaces.

Çelik

- Özellikler: Extremely strong and durable, capable of carrying heavy loads.

- Applications: Best suited for industrial environments where heavy machinery or equipment needs to be moved.

- Avantajları: Highly resilient to rough and uneven surfaces, ideal for outdoor use or in environments with debris.

Paslanmaz çelik

- Özellikler: Combines strength with corrosion resistance.

- Applications: Frequently used in food processing, marine, and medical environments where hygiene and corrosion resistance are crucial.

- Avantajları: Easy to clean, maintaining its appearance and functionality in harsh conditions.

PP (Polypropylene)

- Özellikler: A light, economic option with good resistance to chemicals.

- Applications: Appropriate for light-duty applications such as office equipment or lightweight furniture.

- Avantajları: Does not absorb water, making it suitable for wet or humid conditions.

PVC Tekerler

Avantajları:

- Cost-Effective: PVC casters are generally less expensive than their polyurethane counterparts.

- Good Chemical Resistance: They resist most acids, alkalis, and alcohol.

- Lightweight: PVC casters are lighter, making them suitable for light-duty applications.

Applicable Flooring Types:

- Ideal for carpeted or tiled floors where load requirements are minimal.

Brass

- Özellikler: Offers a classic aesthetic with moderate durability.

- Applications: Common in decorative furniture where style is as important as functionality.

- Avantajları: Provides an elegant look while offering decent resistance to corrosion.

Cast Iron

- Özellikler: Exceptionally strong and able to support very heavy loads.

- Applications: Predominantly used in heavy industry for transporting large machinery or goods.

- Avantajları: Highly durable and capable of withstanding exposure to high temperatures and rough surfaces.

Phenolic

- Özellikler: Made from phenolic resin, these wheels are hard and resist impact, heat, and chemicals.

- Applications: Suitable for industrial environments where floors are not a concern, and durability is key.

- Avantajları: Does not mark floors, resists water, oil, grease, and commonly used solvents.

Each of these materials offers unique benefits and limitations. The choice largely depends on the specific requirements of the application, including load capacity, environmental conditions, and floor type. By understanding the properties of these materials, you can make an informed decision that ensures optimal performance and longevity of your casters.

2. Classification by Load Capacity

The load capacity of a caster is a critical factor in ensuring safety and efficiency. Different casters are designed to support varying weight ranges, making it essential to choose a caster that aligns with the specific load requirements of your application. Here’s an expanded look at the classifications based on load capacity, including typical load range specifications:

Light-Duty Casters

- Load Range: Typically supports up to 250 pounds (approximately 113 kilograms).

- Özellikler: These casters are designed for lightweight applications, offering easy maneuverability and less robust construction.

- Common Uses: Ideal for office furniture, light trolleys, and small machinery.

- Materials: Often made from materials like plastic, light rubber, or thin-gauge steel.

Medium-Duty Casters

- Load Range: Generally supports between 250 to 750 pounds (113 to 340 kilograms).

- Özellikler: Balancing strength with flexibility, these casters are more durable than light-duty ones and can handle moderate weights.

- Common Uses: Suitable for hospital equipment, food service carts, and retail display units.

- Materials: Commonly constructed from rubber, polyurethane, or reinforced plastics.

Ağır hizmet tipi tekerlekler

- Load Range: Designed to support loads from 750 to 3,500 pounds (340 to 1,587 kilograms).

- Özellikler: Built for strength and endurance, these casters can handle substantial weights and often feature robust designs.

- Common Uses: Used in industrial settings for moving large machinery, heavy equipment, and large-scale containers.

- Materials: Typically made from high-grade steel, cast iron, or heavy-duty polyurethane.

Super Heavy-Duty Casters

- Load Range: Capable of supporting loads over 3,500 pounds (1,587 kilograms), with some models designed for loads over 20,000 pounds (9,072 kilograms).

- Özellikler: These are the strongest casters, designed for the most demanding applications with the highest durability and load capacity.

- Common Uses: Essential in heavy industries for moving extremely heavy machinery, large vehicles, or significant structural components.

- Materials: Often constructed from reinforced steel, cast iron, and specialized high-capacity materials.

3. Classification by Mount Method

The installation method of casters is pivotal for ensuring proper attachment, stability, and functionality. Different mounting types cater to various applications, floor types, and mobility needs. Here’s an enriched look at the five common mounting types of casters:

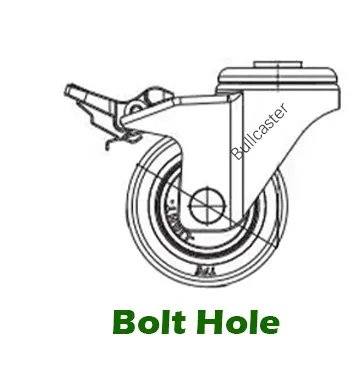

Bolt Hole (Hole Top)

- Description: These casters are mounted using a single bolt through a central hole.

- Özellikler: Provides a secure and easy-to-install solution, ideal for quick replacements or adjustments.

- Applications: Commonly used in light to medium-duty equipment like carts, trolleys, and portable machinery.

- Avantajları: Simplifies installation and is adaptable to a variety of applications where quick mounting is needed.

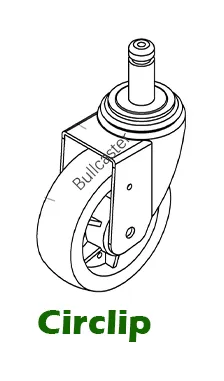

Circlip (Insertion Rod)

- Description: Mounted using a circlip or snap ring that secures the caster stem in a pre-drilled hole.

- Özellikler: Offers a secure fit with easy installation and removal.

- Applications: Ideal for equipment where casters need to be replaced or removed frequently, such as in retail or display units.

- Avantajları: Allows for easy caster replacement and maintenance with minimal tools.

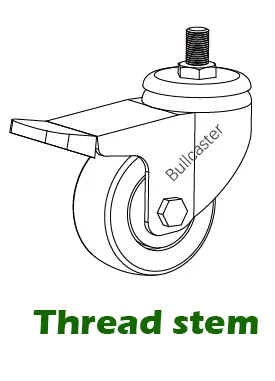

Thread Stem (Screw Rod)

- Description: These casters have a threaded stem for screwing into a corresponding receptacle.

- Özellikler: Provides a highly secure attachment, suitable for both vertical and horizontal loads.

- Applications: Widely used in furniture, office chairs, and equipment where compact and reliable mounting is necessary.

- Avantajları: Offers a strong, stable connection and is excellent for applications with limited space.

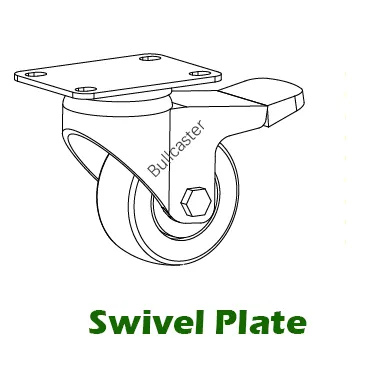

Swivel Plate (Flat Plate)

- Description: Mounted using a flat plate with holes for screws or bolts.

- Özellikler: Offers a broad and stable mounting surface, distributing weight and stress evenly.

- Applications: Common in medium to heavy-duty applications like industrial carts, machinery, and equipment where stability is crucial.

- Avantajları: Provides a robust and secure attachment, suitable for heavier loads.

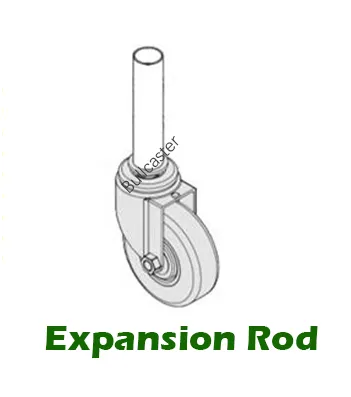

Expansion Rod

- Description: Features a rod that expands inside a tubular leg or framework to secure the caster.

- Özellikler: Provides a versatile and adjustable fit for various tube diameters.

- Applications: Ideal for tubular furniture, hospital beds, and equipment where traditional mounting options are not feasible.

- Avantajları: Enables secure mounting in hollow structures without the need for drilling or threading.

Each caster’s mount method presents unique benefits and is designed for specific types of equipment and applications. Choosing the right mounting type is crucial for ensuring the caster is securely attached, functions correctly, and provides the required mobility and stability for the application.

4. Classification by Caster Bracket Type

The type of caster determines its movement and control capabilities. This classification revolves around how the caster rotates and whether it has additional features like brakes. Here’s an expanded overview of the different rotation types of casters: swivel casters, rigid casters, and brake casters.

Swivel Caster

- Description: Features a wheel mounted on a bearing that allows for 360-degree rotation.

- Özellikler: Provides excellent maneuverability, allowing the attached equipment to change direction smoothly.

- Avantajları: Enhances the ease of steering and changing direction, especially in tight spaces.

- Design Variations: These may include features like locking mechanisms or spring-loaded designs for additional functionality.

- Additional: There are many types of swivel caster brackets. The swivel plate types include single raceway and double raceway. In some heavy-duty casters, a swivel plate with an impact-resistant design is used and equipped with a swivel lock.

Rigid Casters (Directional Wheels)

- Description: Has a fixed wheel orientation, allowing movement in only one direction.

- Özellikler: Offers greater stability and control for straight-line movement.

- Avantajları: Ideal for transporting heavy loads over longer distances in a straight line, as it maintains a steady trajectory.

- Considerations: Limitation in directional change requires sufficient space for turning.

Brake Caster

- Description: Equipped with a braking mechanism that can lock the wheel in place.

- Özellikler: Provides added safety and control, preventing unintentional movement.

- Avantajları: Allows the user to securely lock the equipment in place, ensuring stability during loading, unloading, or when stationary.

- Design Options: Brakes can vary from simple toe-operated locks to more complex locking systems that lock both the wheel and the swivel bearing.

- Additional: There are many types of caster brakes. You can check our detailed introduction on caster brake types.

Understanding the distinct features and applications of each caster type is crucial for selecting the right caster for a specific task. Swivel casters offer flexibility in movement, rigid casters provide stability in straight paths, and brake casters ensure safety and stationary control. The choice depends on the specific requirements of movement, control, and stability needed for your equipment or furniture.

5. Classified by Main Usage Scenarios

Casters are not one-size-fits-all; their design and materials are often tailored to specific usage scenarios. Understanding these scenarios helps in selecting casters that best fit the operational and environmental needs. Here’s an enhanced overview of casters classified by their main usage scenarios:

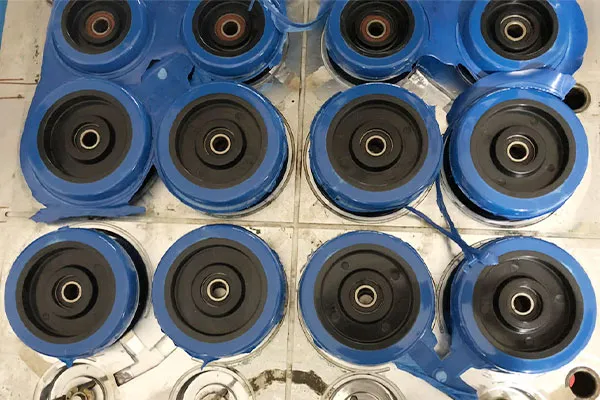

Endüstriyel Tekerlekler

- Özellikler: Built for strength and durability. Often made from heavy-duty materials like PU, Nylon, steel, or cast iron.

- Applications: Used in manufacturing plants, warehouses, and other industrial settings where heavy loads and rugged use are common.

- Special Features: These may include high load-bearing capacity, resistance to chemicals, and the ability to withstand harsh conditions.

Medical Tekerlekler

- Özellikler: Prioritize smooth operation, hygiene, and reduced noise.

- Applications: Common in hospitals and clinics, on equipment such as patient beds, medical carts, and movable medical apparatus.

- Special Features: Typically feature easy-to-clean surfaces, antimicrobial properties, and non-marking materials, like the TPR wheel, to protect hospital floors.

Furniture Wheels

- Özellikler: Combine functionality with aesthetics; often smaller and designed to blend with home or office decor.

- Applications: Used on office chairs, portable tables, and decorative home furniture.

- Special Features: May include a variety of finishes and styles to complement furniture design, and soft treads for floor protection.

Araba Tekerlekleri

- Özellikler: Designed for smooth rolling and easy maneuverability.

- Applications: Found on shopping carts, luggage trolleys, and food service carts.

- Special Features: Often lightweight, with materials like rubber or polyurethane for quiet operation and floor protection.

Shock-absorbing Tekerlekler

- Özellikler: Equipped with mechanisms or materials that absorb shock and reduce vibration.

- Applications: Ideal for transporting delicate items or equipment sensitive to vibrations, like electronic equipment or laboratory instruments.

- Special Features: These may include spring-loaded designs or special tread compounds for vibration dampening.

Shipping Container Tekerlekler

- Özellikler: Built to support heavy containers and withstand the rigors of shipping and handling.

- Applications: Used on large shipping containers, storage bins, and heavy-duty material handling equipment.

- Special Features: High load-bearing capacity, durability, and often larger wheel diameters for easier movement over uneven surfaces.

Kapı Tekerlekleri

- Özellikler: Designed to support large gates and doors, facilitating smooth opening and closing.

- Applications: Common in large industrial gates, garage doors, or large residential gates.

- Special Features: Durable construction to bear the weight of heavy gates, often with weather-resistant materials for outdoor use.

Each type of caster is designed to meet specific requirements and environmental conditions. Understanding these classifications helps in choosing the right caster for any given application.

Ⅲ. How to Choose the Right Type of Caster?

Selecting the appropriate caster for your needs involves considering several factors. Here are some key points to keep in mind when choosing casters:

1. Load Requirement

- Assessing Load Capacity: The foremost consideration is the weight the casters need to support. This includes the weight of the object and any additional load it may carry.

- Safety Margin: Always choose casters with a capacity greater than your maximum load to ensure safety and longevity.

- Calculate your caster load requirements with our online caster load calculator

2. Material Suitability

- Çevre Uyumluluğu: The usage environment plays a crucial role in material selection. Consider factors like exposure to chemicals, moisture, temperature extremes, and floor conditions.

- Material Characteristics:

- For quiet operation and floor protection, rubber or polyurethane might be ideal.

- In environments with chemicals or moisture, stainless steel or nylon would be more suitable.

- For heavy-duty industrial use, materials like steel or cast iron can withstand high loads and rough conditions.

3. Caster Combination

- Balancing Mobility and Stability: A common setup involves combining swivel casters with fixed casters. For example, two-directional wheels (fixed) and two brake wheels (swivel) can provide a good mix of maneuverability and control.

- Application Specifics: Consider the specific maneuvering needs of the application. For instance, in tight spaces, all swivel casters may be more practical.

4. Economic Considerations

- Cost-Effectiveness: While there may be several caster types that meet your requirements, it’s essential to consider the cost-to-benefit ratio.

- Long-Term Value: Cheaper options might not always be cost-effective in the long run. Consider durability and maintenance requirements.

5. Additional Features

- Brakes and Locks: For applications where stability is crucial, consider casters with braking or locking mechanisms.

- Special Features: Features like shock absorption can be critical for delicate equipment, while noise reduction might be essential in a hospital or office setting.

By carefully considering these factors, you can choose the most appropriate caster type for your application, ensuring efficiency, safety, and cost-effectiveness. The right selection not only enhances the functionality of the movable unit but also contributes to the longevity of both the casters and the floors they operate on.

Ⅳ4: Summary

In this comprehensive guide, we’ve explored the various types of casters available, delving into their materials, capacities, installation methods, specific types, and usage scenarios. Understanding these classifications is crucial for selecting the right caster for your specific needs, whether for industrial, medical, furniture, or other applications. The choice of the right caster involves considering load requirements, material suitability, caster combinations, and economic factors to ensure efficiency, safety, and cost-effectiveness.

bulcaster stands at the forefront of innovation and quality in caster manufacturing. Our extensive range of products is designed to meet the diverse needs of our clients across various industries. With our expertise in caster technology, we offer not just products but solutions tailored to your unique requirements.

Are you looking for the perfect caster solution for your business? Look no further than Bullcaster. Our team is ready to assist you in selecting the best casters that align with your operational needs and budget. We provide:

- Expert Guidance: Our knowledgeable team will help you navigate through our extensive product range to find the ideal match for your application.

- Custom Solutions: If you have specific requirements, we can provide custom-designed casters to meet your unique needs.

- Kalite Güvencesi: With Bullcaster, you can be assured of receiving products that are of the highest quality, ensuring durability and reliability.

Bullcaster'la iletişime geçin today to discuss your needs and let us help you roll towards efficiency and success!