I. Challenges Posed by Concrete Floors for Casters

Concrete floors are a ubiquitous feature in various industrial and commercial settings, from bustling factories and sprawling warehouses to outdoor construction sites. Their robustness and durability make them a popular choice, but when it comes to mobility within these spaces, the choice of caster wheels becomes critical. Selecting the right caster material for concrete floors can significantly impact the efficiency and longevity of your equipment.

In this article, we will explore the various caster wheel materials tailored to excel on concrete surfaces. Each material possesses unique characteristics and advantages, allowing you to make an informed decision based on your specific needs. Whether it’s enhancing wear resistance, reducing noise, or accommodating heavy loads, understanding the nuances of caster materials will empower you to optimize your operations.

II. Caster Materials Suitable for Concrete Floors

A. Nylon Casters

Нейлоновые ролики have earned their reputation as a reliable choice for various applications, especially when it comes to navigating the challenges posed by concrete floors. The secret to their success lies in the exceptional properties of nylon as a caster material.

Nylon is renowned for its remarkable wear resistance, making it particularly well-suited for abrasive concrete surfaces. Whether you’re operating in a bustling warehouse or a busy manufacturing facility, nylon casters can handle the constant wear and tear, ensuring longevity and performance.

Moreover, nylon casters boast a high load-bearing capacity, allowing them to effortlessly support heavy loads without succumbing to pressure. This makes them a preferred choice for промышленное оборудование, utility carts, and machinery that operate on concrete floors.

However, it’s important to note that nylon casters may not be the quietest option available. The robust nature of nylon can result in some noise during operation, which may be a consideration in noise-sensitive environments. Despite this potential drawback, their wear resistance and load-bearing capabilities make nylon casters a compelling choice for many concrete floor applications.

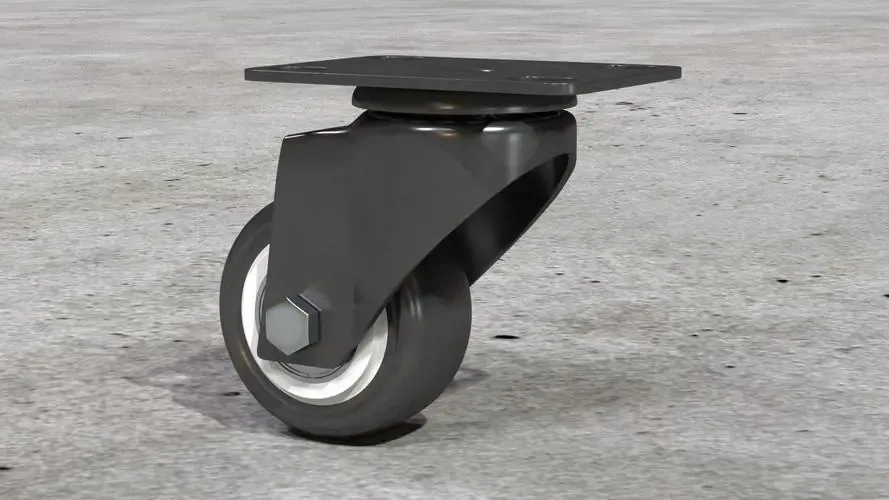

B. Polyurethane Caster

Полиуретановые ролики have gained popularity for their versatility and exceptional performance, especially in settings where silence and wear resistance are paramount. These casters are a top choice for applications that demand both durability and noise reduction.

One of the standout features of polyurethane casters is their ability to move quietly across concrete floors. This makes them an excellent choice for environments where noise pollution is a concern.

Additionally, polyurethane casters offer impressive load-bearing capabilities, making them suitable for a wide range of applications. From medical equipment to retail displays, these casters deliver the necessary strength and durability while maintaining a quiet and smooth operation.

C. Rubber Casters

Резиновые ролики are known for their ability to provide a smooth, silent, and shock-absorbing ride on concrete floors. These casters offer a perfect blend of qualities that make them suitable for a variety of applications, especially in noise-sensitive environments.

The key advantage of rubber casters is their quiet performance. When maneuvering equipment or carts on concrete surfaces, the noise generated is significantly reduced, contributing to a more pleasant and tranquil work environment. This feature makes rubber casters a preferred choice in settings such as hospitals, hotels, and libraries where noise disturbance is undesirable.

Rubber casters also excel in shock absorption, helping protect delicate cargo or sensitive equipment from vibrations and impacts. This is particularly beneficial when transporting fragile goods or when precise movements are required.

However, it’s crucial to consider load-bearing requirements when opting for rubber casters. While they excel in providing a smooth and silent ride, rubber casters may not be suitable for applications demanding exceptionally high single-wheel load capacities exceeding 500kg. In such cases, alternative materials like nylon or metal may be more appropriate.

D. Metal Casters (Cast Iron and Steel)

In the world of heavy-duty applications on concrete floors, metal casters take center stage. This category encompasses both чугунные ролики и steel casters, each with its unique attributes that cater to extreme conditions and substantial weight demands.

Cast Iron Casters:

Cast iron casters are renowned for their robust construction and unmatched durability. The inherent strength of cast iron makes these casters capable of withstanding harsh environments, high-temperature conditions, and extreme loads. They are often used in foundries, manufacturing plants, and construction sites, where the demands on casters are at their peak.

Steel Casters:

Steel casters share many of the same attributes as cast iron casters but offer the added benefit of being more lightweight. They provide exceptional load-bearing capacity and high-temperature resistance, making them suitable for heavy machinery, industrial equipment, and metalworking facilities.

Both cast iron and steel casters are well-equipped to tackle the challenges posed by concrete floors. Their rugged construction and ability to withstand heavy loads make them a top choice for applications where durability and strength are paramount.

E. PVC Casters

PVC casters are known for their unique combination of properties that make them suitable for various applications on concrete floors. These casters are characterized by their high hardness, cost-effectiveness, and flexibility in rotation.

PVC caster wheels are relatively hard, making them capable of rolling smoothly on concrete surfaces. This hardness ensures minimal wear and tear on the caster wheels, leading to increased longevity and cost savings in terms of replacements.

However, it’s important to be aware of the limitations of PVC casters. They may not provide the same level of silent performance as materials like polyurethane or rubber. Additionally, PVC casters may not be suitable for applications with high load requirements, as their load-bearing capacity may be limited compared to other materials.

III. Conclusion

In the world of material handling and mobility on concrete floors, the choice of caster wheels is far from a one-size-fits-all decision. Each caster material brings its unique set of advantages and considerations, and understanding these distinctions is vital for optimizing your operations.

We’ve explored a diverse range of caster materials, each tailored to excel in specific scenarios:

- Нейлоновые ролики stand out with their exceptional wear resistance and impressive load-bearing capacity, making them an ideal choice for enduring the rigors of concrete floors.

- Полиуретановые ролики offer the perfect balance between quiet operation and durability, ensuring smooth and silent mobility while withstanding the abrasive nature of concrete.

- Резиновые ролики provide a serene and shock-absorbing ride, making them ideal for noise-sensitive environments and situations where cargo protection is paramount.

- Metal casters, including cast iron and steel variants, are the heavyweight champions, thriving in extreme conditions and supporting substantial loads with unwavering strength.

- PVC casters offer a unique blend of high hardness, cost-effectiveness, and flexible rotation, making them a versatile choice for various concrete floor applications.

Each material brings its own strengths, making the decision-making process a matter of aligning these attributes with your specific needs.

As you consider the caster material that best suits your requirements, keep in mind factors such as load capacity, noise sensitivity, durability, and cost-effectiveness. By doing so, you can optimize the mobility of your equipment, reduce maintenance costs, and enhance overall efficiency within your facility.

В Булкастер, we understand the critical role that caster wheels play in your daily operations. Our commitment to quality and customization ensures that you find the perfect caster solution for your unique needs. Whether you require silent, high-load, or specialized casters for your concrete floors, we’re here to provide tailored solutions that meet and exceed your expectations.

Take the next step in enhancing your mobility solutions by reaching out to us today.