What is the appropriate way to combine casters? Is it sufficient to randomly install a few wheels on a device? If the combination of casters is unreasonable and does not suit the specific usage environment, it can cause problems during the use of the equipment. The way casters are matched affects the flexibility of the equipment’s movement, its load-bearing capacity, and in some cases, even the working lifespan of the equipment. Next, we will introduce seven common caster combinations, from which you can choose the most suitable caster configuration for your needs.

7 Casters Combinations

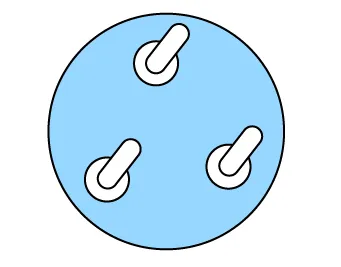

1. 3 Casters (All Swivel)

The first combination: A set of three universal wheels.

Yes, you read that correctly, it involves using three wheels, all of which are universal wheels. This installation combination is suitable for the handling of barrel-shaped or small equipment. It offers better load-bearing capacity and maneuverability compared to the same specification with a four-wheel setup. However, if the surface is uneven, there might be accidents, as this configuration makes it difficult to ensure the equipment moves in a straight line. (The maximum load capacity of each caster is calculated as follows: (Weight of the loaded object + Weight of the platform cart) / 2.5.)

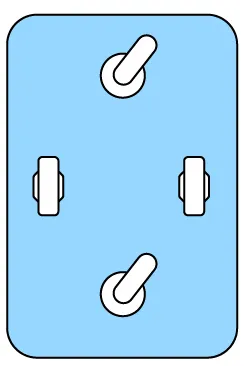

2. 3 Caters (2 Rigid + 1 Swivel)

The combination of two fixed wheels and one universal wheel offers good directional control and is cost-effective. It is suitable for short-distance transportation of low-center-of-gravity, medium-light equipment. However, this combination requires that the load be evenly distributed to ensure stability during movement. (The maximum load capacity of each caster is calculated as follows: (Weight of the loaded object + Weight of the platform cart) / 2.5.)

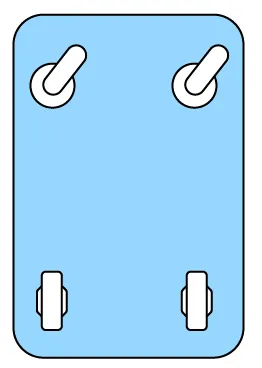

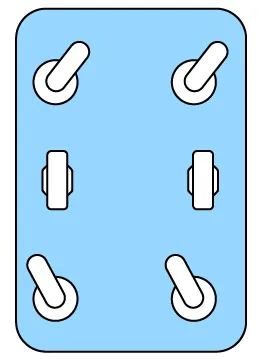

3. 4 Casters (2 Rigid + 2 Swivel)

The combination of two fixed wheels and two universal wheels is the most popular installation method, offering good load capacity and superior operability.

This caster combination ensures precise directional control even over longer distances, making it typically suitable for the transportation of heavy and medium-heavy products. such as trolley carts.

Of course, the choice of wheel diameter should be based on the weight of the load. Generally, the two fixed wheels are installed at the front of the cart, while the two universal wheels are mounted at the rear.(The maximum load capacity of each caster is calculated as follows: (Weight of the loaded object + Weight of the platform cart) / 3.)

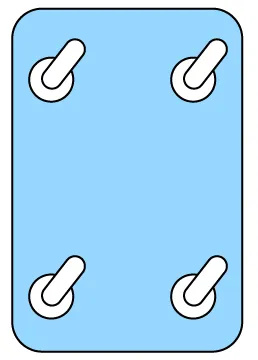

4. 4 Casters (4 Swivel)

The installation combination of four universal wheels is primarily used in special environmental settings, ensuring adjustability and movement in all directions, with a high load capacity. It’s particularly useful in limited spaces due to its small operation radius. This setup is very suitable for environments that require winding movements and lateral displacement. such as shopping carts.

However, it is not recommended for equipment that needs to move in a straight line. Also, on sloped work surfaces, this type of caster combination can be difficult to control. But if two of the universal wheels are equipped with directional lock brakes, they can be locked in a desired direction, effectively transforming the setup into a combination of two universal wheels and two fixed wheels when needed.fixed wheels are installed at the front of the cart, while the two universal wheels are mounted at the rear.(The maximum load capacity of each caster is calculated as follows: (Weight of the loaded object + Weight of the platform cart) / 3.)

5. Diamond Combination (4 Rigid)

The installation of four fixed casters in a diamond shape is the most economical method but is only suitable for transporting lightweight objects.

In this diamond layout, the two central fixed casters are approximately 25mm taller than the two end fixed casters, creating a sloped arrangement. Alternatively, the middle two fixed wheels can be mounted directly on the main axle with wheels.

In this diamond-shaped layout, the four fixed wheels support the load alternately, primarily relying on the middle two casters for strength. This installation method requires careful stacking of the load, as it is prone to toppling. It is not recommended for use on sloped surfaces.(Weight of the loaded object + Weight of the platform cart) / 2.)

6. Diamond Combination (2 Rigid+ 2 Swivel)

The installation of four casters in a diamond shape offers strong load capacity. In this diamond layout, the two central fixed casters are about 25mm taller than the two end universal wheels, creating a sloped arrangement. Alternatively, the middle two fixed wheels can also be directly mounted on the main axle.

This diamond-shaped layout of four casters supports the load alternately, with the main force borne by the two middle casters. Compared to a setup with four fixed wheels, this arrangement offers better directional control in smaller spaces. However, this installation method demands careful stacking of the load, as it is prone to toppling. It is not recommended for use on sloped surfaces. (Weight of the loaded object + Weight of the platform cart) / 2.)

7. 6 Casters Combination (4 Swivel+2Rigid)

This combination, featuring six casters in a specific layout, offers strong load capacity, excellent maneuverability, and stability, making it commonly used for longer platform carts.

In this layout, the two central fixed casters are approximately 25mm taller than the four universal wheels at the ends, creating a sloped arrangement. The central fixed wheels can also be directly mounted on the main axle instead.

The six casters in this layout support the load alternately, with the main force borne by the two middle casters. Therefore, these middle wheels must have a strong load-bearing capacity. This installation method requires careful stacking of the load, as it is prone to toppling. It is not recommended for use on sloped surfaces. (Weight of the loaded object + Weight of the platform cart) / 2.)

Conclusion

The proper matching of casters on equipment significantly affects its operational flexibility, load capacity, and lifespan. Various combinations, such as three universal wheels, a mix of fixed and universal wheels, or diamond-shaped layouts, cater to different needs like maneuverability in tight spaces or stability for heavy loads. The choice depends on the equipment’s size, weight, and operational environment. Careful consideration is required, especially on uneven or sloped surfaces, to ensure safety and efficiency.

If you have any questions when using casters, you can contact us. After all, we are professionals in making casters and selling casters!