Industrial Caster Manufacturer

Bullcaster supplies industrial casters in a variety of materials and applications, we can meet almost any industrial caster need you have.

Leading Industrial Caster Suppliers

There are many types of industrial casters produced by Bullcaster.

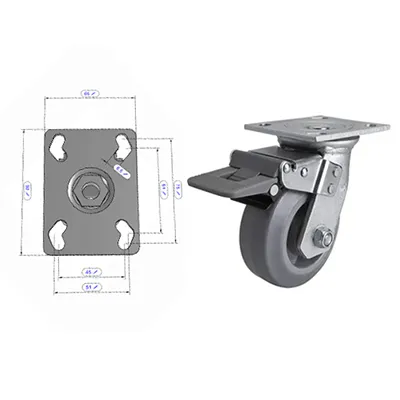

According to the material, we produce rubber casters, polyurethane casters, cast iron casters, nylon casters, and steel casters; according to the load, we produce light casters, heavy-duty casters, heavy-duty casters, and extra-heavy-duty casters; according to the structure Divided, we produce fixed casters, swivel casters, casters with brakes and swivel casters; according to size, we produce 2, 4, 5, 6, 8, 10-inch industrial casters; and support a variety of bracket surface treatment processes, such as plating Zinc casters, electrophoretic painted casters, stainless steel casters, powder coated casters.

In addition, we can customize industrial casters for you according to your needs, such as wheel diameter and width, bracket thickness, load capacity, brake type, etc.

For your upcoming industrial caster needs, please get in touch with our product experts and we will provide you with a quote and solution.

Industrial Caster Wheels Series

Nylon Caster Wheels

Nylon industrial casters are known for their durability, corrosion resistance, and smooth rolling on various surfaces. They offer excellent load-bearing capacity, reduced friction, and resistance to chemicals and moisture. Nylon casters are lightweight, cost-effective, and suitable for a wide range of applications, making them a popular choice in material handling equipment.

Rubber Caster Wheels

Rubber industrial casters are known for their shock-absorption properties, which reduce noise and vibration. They offer good traction and floor protection, making them suitable for delicate surfaces. Rubber casters also provide smooth and quiet mobility, making them ideal for applications where noise and floor protection are important.

Cast Iron Casters

Cast iron industrial casters are robust and capable of handling heavy loads. They provide excellent stability and durability, even in harsh environments. These casters are resistant to wear and tear, making them ideal for industrial settings where strength and longevity are essential.

Stainless Steel Casters

Stainless steel industrial casters are corrosion-resistant and offer exceptional durability, even in harsh and corrosive environments. They provide high load-bearing capacity, longevity, and easy maintenance. These casters are ideal for applications where hygiene, cleanliness, and resistance to rust are crucial.

Steel Caster Wheels

Steel industrial casters are strong and durable, capable of handling heavy loads in tough environments. They provide excellent stability and impact resistance. Steel casters are often cost-effective and offer a good balance of strength and versatility, making them suitable for a wide range of industrial applications.

Super Duty Caster Wheels

Super Duty industrial casters are designed for extreme load-bearing capacity, often exceeding 1,000 pounds per caster. They feature heavy-duty construction with reinforced components for exceptional strength and durability. These casters are ideal for applications requiring maximum weight support and reliability in industrial and commercial settings.

Leveling Casters

Leveling industrial casters are equipped with adjustable leveling mechanisms, allowing for precise height adjustment and stability on uneven surfaces. They are ideal for applications requiring both mobility and stability, such as machinery or equipment that needs to be leveled and moved with ease.

High Heat Casters

High heat industrial casters are designed to withstand extreme temperatures, typically up to 750°F (400°C) or more. They are constructed with specialized heat-resistant materials like stainless steel and high-temperature wheels. These casters are ideal for applications in industries such as foundries, bakeries, and steel mills.

Custom Casters Wheels

If you need customized industrial casters now, such as special sizes, load requirements, additional accessories, customized installation dimensions, etc., please contact our engineers. The demand list, drawings and pictures will help our engineers quickly provide a solution plan.

Industrial Castors with Best Service

Free Sample

We provide free samples of casters, which will help you test the casters quality.

Fast Delivery

We can deliver most casters within 7 days to ensure the progress of your project.

Shipping Support

We can provide you with shipping services, saving you time and energy.

Customizable

Bullcaster casters support customization to meet your diverse needs.

Industrial Wheels and Castors Applications

Machinery & Equipment

Industrial casters are integral components in the machinery and equipment industry, enhancing the versatility and functionality of various machines. In manufacturing plants, casters enable the easy mobility of heavy machinery, facilitating efficient reconfiguration and maintenance. They’re crucial for medical equipment, allowing healthcare professionals to move vital devices with precision. In the construction sector, casters simplify the transport of tools and materials across job sites, increasing productivity.

To optimize your machinery and equipment with the right caster solutions, contact us today.

Logistics Industry

Industrial casters play a vital role in the logistics industry by enhancing the mobility and efficiency of material handling processes. They are extensively used in warehouses and distribution centers to move heavy pallets and goods with ease. Casters with swivel capabilities allow for quick direction changes, improving maneuverability in tight spaces. In e-commerce fulfillment centers, these casters aid in the swift movement of products, ensuring timely deliveries.

Our team of experts is ready to provide you with the ideal caster options that meet your specific needs.

Factory

Industrial casters are indispensable in factories across diverse sectors. In automotive manufacturing, they enable the easy movement of heavy vehicle parts and assemblies, streamlining production processes. In textile factories, casters assist in transporting large rolls of fabric, enhancing efficiency. Food processing plants rely on casters to maneuver equipment, ensuring seamless food production. Pharmaceutical facilities use them for the mobility of machinery, maintaining stringent hygiene standards.

For tailored industrial caster solutions that boost productivity and efficiency in your factory, contact us today.

Commercial

Industrial casters find diverse commercial applications across various industries. In supermarkets, they facilitate the smooth movement of shopping carts, enhancing the shopping experience. Airports rely on heavy-duty casters to transport luggage efficiently, ensuring timely departures and arrivals. In the catering industry, casters are essential for maneuvering heavy kitchen equipment, simplifying food preparation.

Don’t miss the opportunity to enhance your operations with our high-quality casters. Reach out to us now to get started!

Top-Industrial Caster and Wheel Company

Bullcaster is a top industrial caster and wheel company, We are located in Guangdong Province, the world’s caster industry gathering place.

As a company with ten years of caster production and export experience, we serve more than 300 customers every year. Our excellent quality and perfect services have helped many customers achieve great commercial success.

If you are looking for a stable caster supplier, please try to get in touch with us, our high-quality products and services will definitely help your business grow.

Produced Based on ISO9001 Certificate

Bullcaster is an ISO9001 certified industrial caster manufacturer. We ensure our production efficiency and caster quality by using an efficient and strict management system.

We will strictly manage every production link of casters, such as raw material inspection, wheel injection molding, bracket stamping molding, caster assembly, caster testing, packaging, delivery, and other production links.

Suppliers with stable quality and timely delivery must be your best choice.

Bullcaster: Industrial Wheel Manufacturers

Advantages of Bullcaster

A. High-Quality Raw Materials

All Bullcasterd wheels use brand new plastic particles as raw materials and do not use secondary recycled raw materials, which ensures the impact resistance and tear resistance of the caster wheels.

B. A Grade caster bracket steel plate

Bullcaster has always used steel with a thickness that meets industry standards as the raw material for caster brackets and does not use recycled steel as raw materials for caster brackets, which ensures the load-carrying capacity and safety of the casters.

We Are Always Doing Better

C. Good Quality Bearing

For the bearings inside the casters, Bullcaster will not use low-quality bearings to save costs. Our high-quality bearings improve the rotation flexibility and load-carrying capacity of the casters while reducing the running noise of the casters.

D. Perfect Delivery Support

All goods will be strictly packed before shipment. We use PP bags + cartons + woven bags + bandages + plastic pallets + waterproof films to package the goods to avoid damage to the casters due to transportation.

Frequently Asked Questions

1. Durability: Industrial casters are built to withstand heavy loads, frequent use, and harsh environments. They are constructed with robust materials and reinforced components to ensure longevity and reliability.

2. Load Capacity: Industrial casters typically have higher weight-bearing capacities compared to regular casters. They can support substantial loads, making them suitable for industrial machinery, equipment, and materials.

3. Specialized Materials: Industrial casters are often made from materials like steel, stainless steel, nylon, or rubber, chosen for their strength, durability, and resistance to wear and corrosion. These materials are selected to match the specific needs of industrial applications.

4. Versatility: While regular casters are commonly used for lighter tasks and furniture, industrial casters are designed to handle a wide range of applications, including manufacturing, logistics, healthcare, and construction.

5. Options and Customization: Industrial casters come in various configurations, including swivel, rigid, and brake options. They can be customized to meet specific requirements, such as high-temperature environments, anti-static properties, or special wheel materials.

Selecting the right industrial caster for your specific application is crucial to ensure optimal performance and longevity. Consider the following factors when making your choice:

1.Load Capacity:*Determine the maximum weight the caster will need to support. Choose casters with a load capacity well above the heaviest load they will bear to ensure safety and longevity.

2. Floor Type: Consider the type of flooring in your facility. Different casters are designed for various surfaces, such as concrete, tile, carpet, or specialty flooring. Select casters that won’t damage the floor and provide smooth mobility.

3. Mobility Requirements: Assess how the equipment or machinery needs to move. Swivel casters provide maneuverability in all directions, while rigid casters move in a straight line. Consider a combination of both for optimal control.

4. Environmental Conditions: Factor in the environment in which the casters will operate. For extreme temperatures, high humidity, or corrosive environments, choose casters made from materials that can withstand these conditions, such as stainless steel or high-temperature-resistant materials.

5. Chemical Exposure: If the casters will be exposed to chemicals, oils, or solvents, select casters that are chemically resistant to prevent corrosion and deterioration.

6. Shock and Vibration: For applications with frequent impacts or vibrations, choose casters designed to absorb shocks and reduce noise, such as those with shock-absorbing or pneumatic wheels.

7. Mounting Type: Determine the mounting style of the caster, such as plate mount or stem mount, and ensure it matches your equipment’s mounting configuration.

8. Braking Options: If stability is crucial, consider casters with locking mechanisms or brakes to prevent unwanted movement.

9. Wheel Material: Select the wheel material that best suits your application.

10. Cost: While it’s essential to meet your application’s requirements, consider your budget and choose casters that offer the best balance of performance and affordability.

Yes.

Before we provide you with a reference caster load, please send us your caster usage scenarios, mobility requirements, maximum required load weight, etc.

One-Stop Industrial Wheels Ltd

If you still have questions, then send us an inquiry directly and our sales experts will solve all your problems.