Heavy Duty Caster Wheels Manufacturer

Get any style of heavy-duty casters from Bullcaster, we have over 1000+sku to choose from. We can produce almost any heavy-duty caster for you.

Heavy Caster Company

Bullcaster is a top heavy-duty caster supplier with ten years of production experience. We provide heavy-duty caster solutions to hundreds of users every year and help them achieve commercial success. Our heavy-duty casters are widely used in the furniture industry, industrial industry, medical industry, and logistics industry.

Our heavy-duty caster materials include: PA, nylon, polyurethane, steel, cast iron, stainless steel and other materials; heavy-duty caster sizes include: 1 inch, 2 inch, 3 inch, 4 inch, 5 inch, 6 inch, 7 inch, 8 inch , 10, 12, and 14 inches are available; the maximum load can reach 10,000 lbs.

In addition, we can also provide you with customized services for heavy-duty casters, such as wheel size, mounting holes, bracket type, additional parts, etc. You can provide samples or drawings, and we can produce customized products for you.

For any upcoming projects that require heavy casters, please contact us and we will explore how best to meet your needs.

Heavy Duty Casters Series

Heavy Duty Steel Casters

Heavy-duty steel casters are robust and durable wheels designed to support substantial weight loads and withstand rugged environments. They feature solid steel construction, high load-bearing capacities, precision bearings, and swivel mechanisms for ease of mobility. These casters are ideal for industrial and commercial applications where strength and reliability are essential.

Heavy Duty Cast Iron Wheels

Heavy-duty cast iron wheels are known for their exceptional strength and durability. They feature a solid cast iron construction, capable of supporting heavy loads with ease. These wheels are resistant to wear, tear, and extreme conditions, making them suitable for industrial and heavy-duty applications, providing stability and long-lasting performance.

Heavy Duty Pneumatic Casters

Heavy-duty pneumatic casters have robust, air-filled tires that offer excellent shock absorption and cushioning. They provide a smooth ride and can navigate uneven surfaces with ease. These casters are ideal for applications where minimizing shock, noise, and vibration is essential, such as in manufacturing and material handling.

Heavy Duty Leveling Casters

Heavy-duty leveling casters are designed for stability and easy adjustment. They feature a built-in leveling mechanism that allows precise height control to compensate for uneven surfaces. These casters are suitable for applications where maintaining a level and stable platform is crucial, such as medical equipment and machinery.

Heavy Duty Rubber Wheels

Heavy-duty rubber caster wheels are durable and shock-absorbent. They have a solid rubber tread that provides a smooth and quiet operation while protecting floors. These wheels are ideal for heavy loads, reduce vibrations, and offer good traction, making them suitable for industrial and institutional applications.

Heavy Duty Polyurethane Casters

Heavy-duty polyurethane casters are known for their durability and load-bearing capacity. They feature a solid polyurethane wheel that offers excellent abrasion resistance, chemical resistance, and quiet operation. These casters are ideal for demanding industrial and warehouse applications where reliability and performance are crucial.

Heavy Duty Nylon Caster Wheels

Heavy-duty nylon caster wheels are robust and versatile. They have a durable nylon construction that is resistant to chemicals, impact, and wear. These wheels offer smooth and quiet mobility, making them suitable for various industrial and commercial applications.

Super Heavy Duty Casters

Super heavy-duty casters are engineered for the most demanding applications. They typically feature reinforced steel construction, high load capacities, precision ball bearings, and specialized wheel materials designed to withstand extreme weight loads and rigorous use. These casters are ideal for industrial and heavy machinery applications.

Scaffolding Wheel Heavy Duty

Scaffolding wheels, heavy-duty, are designed for construction scaffolds. They feature robust materials, such as steel or rubber, for durability and stability. These wheels are equipped with swivel mechanisms and brakes, allowing easy movement and secure positioning, enhancing safety and mobility on construction sites.

Heavy Duty Casters Applications

Warehouse Logistics

In the logistics industry, heavy-duty casters are vital for the smooth mobility of material handling equipment, such as carts, pallet jacks, and distribution racks. They enable efficient transportation of heavy loads within warehouses and distribution centers. Key requirements for heavy-duty casters in logistics include high load-bearing capacity, durability, smooth rolling on uneven surfaces, and resistance to wear and tear. Additionally, swivel and locking features are essential for precise maneuverability and stability, ensuring the safe and efficient movement of goods throughout the supply chain.

Healthcare

In healthcare, heavy-duty casters are crucial for medical equipment, hospital beds, and mobile carts, facilitating the easy and precise positioning of equipment and ensuring efficient patient care. Requirements for heavy-duty casters in healthcare include a high weight capacity to support medical devices, quiet and smooth rolling for patient comfort, corrosion resistance for sterilization, and non-marking wheels to maintain hygiene standards. Moreover, the ability to lock the casters securely in place is essential to prevent unwanted movement during medical procedures and ensure patient safety.

Aerospace and Automotive

In the aerospace and automotive industries, heavy-duty casters are used for the mobility of large components and assemblies during assembly, painting, and maintenance processes. Requirements for heavy-duty casters in these industries include high load capacity to support heavy aircraft and vehicle parts, precision maneuverability for tight spaces, non-marking wheels to protect sensitive surfaces, and resistance to chemicals and fluids used in aircraft and automotive maintenance. Additionally, casters must meet strict safety and quality standards, ensuring the reliability and stability required for the delicate tasks of aircraft and automotive maintenance and production.

Manufacturing

In manufacturing, heavy-duty casters are used on machinery and equipment to facilitate easy movement for maintenance, reconfiguration, and transporting goods in the production process. The requirements for heavy-duty casters in manufacturing include high load-bearing capacity, durability to withstand frequent use, and resistance to harsh industrial environments. They must provide smooth and precise rolling, reducing friction and wear on floors while supporting heavy machinery. Furthermore, these casters often need to have locking mechanisms to ensure safety during operation and prevent unintended movement, contributing to the overall efficiency and flexibility of manufacturing processes.

Heavy Duty Castors Service

Free Sample

Bullcaster provides free caster sample service, you only need to pay the shipping fee to get our samples.

Fast Delivery

We can achieve fast delivery within 7-10 days to ensure that you can receive the goods in time.

Shipping Support

We can provide cargo transportation services, sea transportation, land transportation, air transportation

Custom Service

If you have casters drawings or samples, we can customize casters for you.

Top Heavy Duty Castor Wheels Manufacturer- Bullcaster

Bullcaster will be your reliable heavy caster supplier. We have a 20,000-square-meter factory, 100+ workers, and an experienced trade team of more than 10 people.

Many times you need unique and fast caster solutions, and we happen to have extensive production and customization experience, we can provide you with the best caster solutions to help you save time and costs.

Strict Quality Control Process

Quality is the basis of our survival. All Bullcaster caster production is based on the ISO quality management system. Our quality supervision covers the selection of raw materials, wheel injection molding, assembly, quality inspection, testing, packaging, and other processes to ensure that our customers receive the best quality. Every wheel is of high quality.

Why Choose Bullcaster?

You definitely want to work with a reliable caster supplier, then we are. We are always striving to do better

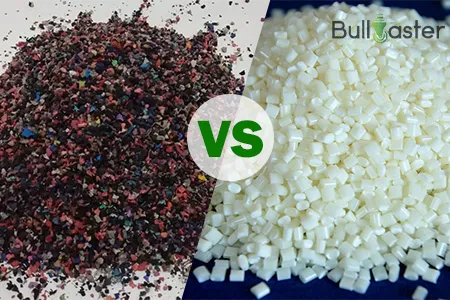

1. High-quality raw materials: Heavy-duty casters are often used in many industrial scenarios, which require high quality of the wheels. We have always used high-quality wheel raw materials to produce casters and do not use recycled plastic particles to ensure the impact resistance and service life of the casters.

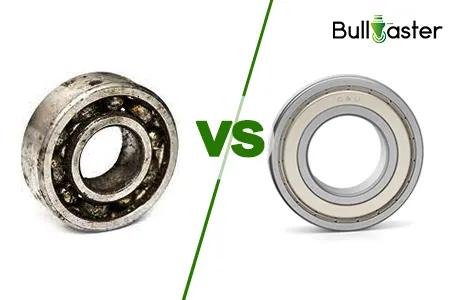

2. Better bearings: The quality of the bearings affects the operating flexibility and load-bearing capacity of the casters. We always choose high-quality bearings to install on the casters to ensure that the casters can operate flexibly for a long time.

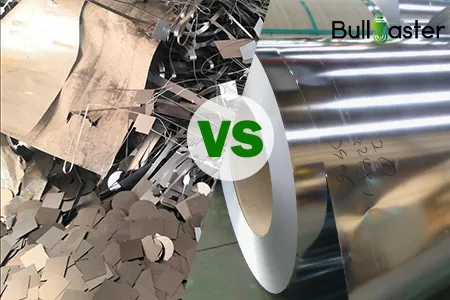

3. Better steel: We choose steel plates with standard thickness as caster brackets. The thickness of our heavy-duty caster brackets is 3.5mm-12mm, which ensures the load-bearing capacity and service life of the casters.

Let Bullcaster grow your business now!

Purchase High Quality Caters Now

For inquiries, quotations, or questions, send us an inquiry now and we will reply to you within 24 hours.