Introduction to the Caster Wheels Industry

1. Casters History and What are Casters?

Casters are devices used to facilitate the movement of objects by attaching them to the bottom of the object. They typically consist of a wheel or set of wheels mounted to a frame or bracket. Casters are commonly used on furniture, industrial equipment, and other objects that need to be easily moved.

The history of casters dates back to the ancient Egyptians, who used wheeled devices to move heavy objects. The Greeks and Romans also used wheeled devices, but it wasn’t until the 18th century that casters, as we know them today, were invented. The first caster with a swivel mechanism was patented in 1776 by Abraham Derby, a British inventor. In the 19th century, the Industrial Revolution led to the widespread adoption of casters in factories and warehouses. Today, casters are essential components in many industries, including healthcare, hospitality, retail, and logistics.

2. What are the Types of Casters Wheel?

① According to the type of caster wheel material

Based on the material of the wheels, casters can be classified into several types. Here are some of the most common types of casters based on the material of the wheels:

A. Rubber casters:

These casters have wheels made of rubber, which provide good traction and shock absorption. They are commonly used in applications where noise reduction is important, such as in hospitals and schools.

B. Polyurethane casters:

These casters have wheels made of polyurethane, which is durable and provides good load capacity. They are commonly used in heavy-duty applications and in environments where chemical resistance is important.

C. Steel casters:

These casters have wheels made of steel, which provide excellent load capacity and durability. They are commonly used in industrial and heavy-duty applications.

D. Nylon casters:

These casters have wheels made of nylon, which provides good load capacity and durability. They are commonly used in applications where floor protection is important, such as in offices and homes.

E. Phenolic casters:

These casters have wheels made of phenolic resin, which provides good load capacity and durability. They are commonly used in heavy-duty applications, such as in factories and warehouses.

② Classification of caster types according to load range

Based on the load capacity, casters can be classified into several types. Here are some of the most common types of casters based on their load capacity:

| Load Capacity Type | Load Capacity Value |

|---|---|

| Light-duty casters | Up to 150 pounds per caster |

| Medium-duty casters | Up to 500 pounds per caster |

| Heavy-duty casters | Up to 2,000 pounds per caster |

| Extra-heavy-duty casters | More than 2,000 pounds per caster |

| Super-heavy-duty casters | More than 10,000 pounds per caster |

3. What are the Applications of Casters?

Casters have a wide range of applications across many industries due to their ability to facilitate the movement of heavy objects and equipment. Some of the most common application fields of casters include:

Material handling and logistics: Casters are commonly used in the transportation of goods and materials within warehouses, distribution centers, and manufacturing facilities. They can be found on carts, dollies, pallet jacks, and other equipment used for moving heavy loads.

Healthcare: Casters are widely used in the healthcare industry for patient beds, medical carts, and other equipment that needs to be moved around the facility. Casters with antimicrobial properties are often used to prevent the spread of germs.

Foodservice: Casters are used in the food service industry for equipment such as serving carts, cooking equipment, and storage racks. Casters made of food-grade materials and with easy-to-clean surfaces are often used to meet safety and hygiene requirements.

Retail: Casters are used in retail environments for displays, clothing racks, and other equipment that needs to be moved around the store.

Office furniture: Casters are often used on office chairs, desks, and filing cabinets to allow for easy movement and reconfiguration of the workspace.

Global Caster Wheel Market Analysis

1. Global Caster Wheel Market Size

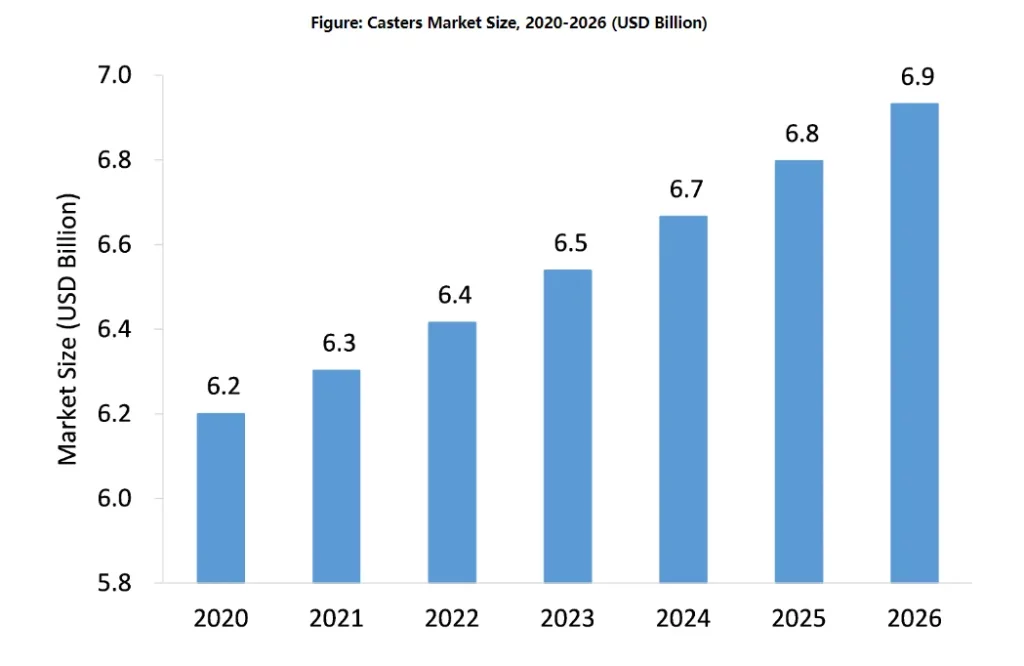

According to research data from Stratview research, the market capacity of casters is expected to grow from US$6.2 billion in 2020 to US$7.6 billion in 2028, at a CAGR of approximately 2.0% during the forecast period.

2. Major Demand Countries for Caster Wheels

It’s difficult to determine the exact countries with the largest demand for casters as this can vary based on a variety of factors, such as the specific industries and applications that require casters. However, based on market research and industry reports, we list 8 countries that have a significant demand for casters:

United States: The United States is a major consumer of casters, with significant demand in industries such as material handling, healthcare, and food service.

China: As a major manufacturer of a wide range of products, China is also a significant consumer of casters. The country’s growing logistics and e-commerce industries have also increased the demand for casters in recent years. more and more global customers looking for caster wheels from China.

Germany: Germany has a strong manufacturing industry, and casters are widely used in factories and warehouses for the transportation of goods.

Japan: Japan has a large automotive industry, which requires casters for the movement of heavy equipment and materials.

United Kingdom: The United Kingdom has a significant demand for casters in the healthcare and food service industries.

France: France has a strong manufacturing industry, and casters are widely used in factories and warehouses for the transportation of goods.

Canada: Canada has a significant demand for casters in industries such as healthcare, material handling, and retail.

Australia: Australia has a significant demand for casters in industries such as healthcare, food service, and logistics.

3. Which Types of Casters Are the Most in Demand?

The types of casters that are most in demand in the market can vary depending on the specific industry and application. Based on market research, industry reports, and the sales data of Bullcaster in the past 10 years. here are 4 types of casters that are commonly in high demand:

① Swivel casters

Swivel casters are versatile and allow for 360-degree rotation, making them ideal for equipment that needs to change direction frequently. They are commonly used in industries such as material handling, healthcare, and food service.

② Heavy-duty casters

Heavy-duty casters are designed to support heavier loads and are commonly used in industries such as manufacturing, construction, and transportation.

③ Stainless steel casters

Stainless steel casters are resistant to rust and corrosion, making them ideal for use in harsh environments such as food service, marine, and chemical processing industries.

④ Pneumatic casters

Pneumatic casters are filled with air and provide a cushioned ride, making them ideal for transporting delicate or fragile items. They are commonly used in industries such as healthcare, hospitality, and retail.

4. What Are the Characteristics of the Caster Industry

① More than 4000 SKUs in the caster industry

The caster industry has a vast range of products with more than 4000 SKUs available in the market. This reflects the diverse range of applications and industries that casters are used in, from healthcare and material handling to retail and office furniture.

②. The main suppliers of casters are concentrated in China

The concentration of major suppliers in China: The caster industry is dominated by Chinese manufacturers who account for a significant share of the global market. This is due to several factors, including the country’s large manufacturing base, low labor costs, and high production capacity. Many of the world’s leading caster suppliers are based in China, and this concentration of suppliers has helped to drive down prices and increase competition in the market.

③ 20% of customers have customized needs on casters

Customization needs: The caster industry has a high level of customization needs due to the varied requirements of different industries and applications. Many users require casters that are tailored to their specific needs in terms of load capacity, wheel material, and design. Customization can also extend to branding and packaging, as many companies require their logos and branding to be incorporated into the products they purchase.

As a result, many caster suppliers offer caster customization services to meet the unique needs of their customers. 25% of Bullcasters’ customers have customized needs, We have solved custom needs for hundreds of clients.

Top 15 Casters Manufacturers and Suppliers in the World

1. Tente Casters Inc.

Tente Casters Inc. is a global manufacturer of high-quality caster wheels and solutions for various industries such as medical, institutional, logistics, and industrial applications. With headquarters in Germany, the company has a strong presence in over 100 countries around the world, including the United States, where they have a subsidiary.

Tente Casters offers a wide range of products including casters, wheels, and accessories. Their products are engineered for durability, reliability, and versatility. They are designed to meet the needs of different applications, from heavy-duty industrial equipment to medical equipment that requires high mobility and ease of use.

2. Colson Group

Colson Group is a leading global manufacturer and supplier of caster and wheel products for a wide range of industries including automotive, aerospace, healthcare, retail, and material handling. The company has a rich history dating back to 1885 when it was founded as the Colson Corporation.

Today, Colson Group has over 25 manufacturing and distribution facilities around the world, and they offer a comprehensive range of caster and wheel solutions. Their product line includes industrial, institutional, and medical casters, as well as wheels for hand trucks, dollies, and other material handling equipment.

3. Blickle Wheels and Casters

Blickle Wheels and Casters is a family-owned global manufacturer of high-quality wheels and casters, based in Rosenfeld, Germany. The company was founded in 1953 and has since become a leading supplier of wheels and casters for various industries, including material handling, medical, food processing, and automotive.

Blickle offers a wide range of products, including wheels, casters, leveling casters, and swivel casters, as well as custom solutions designed to meet specific customer needs. Their products are known for their durability, reliability, and versatility, and they are used in a variety of applications, from heavy-duty industrial equipment to medical carts and furniture.

4. Bullcaster Co.,Ltd China

Bullcaster, A reliable supplier of high-quality casters in Foshan City, Guangdong Province, China. With years of experience in the caster industry, we provide a wide range of casters for various applications at competitive prices. We are committed to delivering exceptional casters’ customer service and providing personalized solutions tailored to our client’s specific needs.

5. RWM Casters company

RWM Casters is a leading manufacturer of high-quality industrial casters and wheels, based in Gastonia, North Carolina. The company was founded in 1988 and has since become a trusted supplier of caster solutions for various industries, including aerospace, automotive, industrial manufacturing, and logistics.

RWM Casters offers a wide range of products, including heavy-duty casters, kingpin fewer casters, dual-wheel casters, shock-absorbing casters, and more. They also provide custom caster solutions designed to meet specific customer requirements. Their products are known for their durability, reliability, and performance, and they are used in demanding applications around the world.

6. Albion Industries Inc.

Albion Industries Inc. is a leading manufacturer of casters and wheels for various industries, including automotive, aerospace, healthcare, and material handling. The company was founded in 1947 and is based in Swartz Creek, Michigan, with additional facilities in Indiana and Texas.

Albion Industries offers a comprehensive range of products, including heavy-duty casters, light-duty casters, and specialty casters for unique applications. They also provide custom caster solutions designed to meet specific customer requirements. Their products are known for their durability, reliability, and performance, and they are used in demanding applications around the world.

7. Darcor Limited

Darcor Limited is a leading manufacturer of ergonomic caster solutions for various industries, including healthcare, hospitality, and material handling. The company was founded in 1932 and is based in Toronto, Canada.

Darcor Limited offers a wide range of products, including medical and hospital casters, heavy-duty casters, and ergonomic casters designed to reduce workplace injuries and improve worker productivity. They also provide custom caster solutions designed to meet specific customer requirements. Their products are known for their durability, reliability, and performance, and they are used in demanding applications around the world.

8. Hamilton Caster & Mfg. Co.

Hamilton Caster & Mfg. Co. is a leading manufacturer of industrial casters, wheels, carts, and trailers for various industries, including aerospace, automotive, material handling, and manufacturing. The company was founded in 1907 and is based in Hamilton, Ohio.

Hamilton Caster & Mfg. Co. offers a comprehensive range of products, including heavy-duty casters, light-duty casters, specialty casters, and trailers for industrial and commercial use. They also provide custom caster solutions designed to meet specific customer requirements. Their products are known for their durability, reliability, and performance, and they are used in demanding applications around the world.

Whether you need casters for industrial equipment, office furniture, medical devices, or any other application, we have the expertise and resources to meet your needs. Contact us today to learn more about our products and services and discover why Bullcaster is the right choice for your caster needs.

9. Jarvis Caster Company

Jarvis Caster Company is a manufacturer of industrial casters and wheels for various industries, including automotive, aerospace, and material handling. The company was founded in 1975 and is based in Cleveland, Ohio.

Jarvis Caster Company offers a wide range of products, including heavy-duty casters, light-duty casters, dual-wheel casters, and specialty casters for unique applications. They also provide custom caster solutions designed to meet specific customer requirements. Their products are known for their durability, reliability, and performance, and they are used in demanding applications around the world.

10. MedCaster

MedCaster is a manufacturer of medical casters and wheels for various healthcare applications, including hospital beds, stretchers, carts, and other medical equipment. The company was founded in 2001 and is based in La Grange, Illinois.

MedCaster offers a wide range of products, including medical and hospital casters, light-duty and heavy-duty casters, and ergonomic casters designed to reduce workplace injuries and improve worker productivity. They also provide custom caster solutions designed to meet specific customer requirements. Their products are known for their durability, reliability, and performance, and they are used in demanding applications in the healthcare industry.

11. Payson Casters

Payson Casters is a manufacturer of industrial and commercial casters and wheels for various applications. The company was founded in 1903 and is based in Gurnee, Illinois.

Payson Casters offers a comprehensive range of products, including heavy-duty casters, light-duty casters, dual-wheel casters, and specialty casters for unique applications. They also provide custom caster solutions designed to meet specific customer requirements. Their products are known for their durability, reliability, and performance, and they are used in demanding applications around the world.

12. Magnus Mobility Systems Inc.

Magnus Mobility Systems Inc. is a manufacturer of mobility products for various applications, including medical equipment, material handling, and retail displays. The company was founded in 1993 and is based in Toronto, Canada.

Magnus Mobility Systems offers a wide range of products, including medical casters and wheels, light-duty and heavy-duty casters, and mobility solutions for unique applications. They also provide custom caster solutions designed to meet specific customer requirements. Their products are known for their durability, reliability, and performance, and they are used in demanding applications around the world.

13. Manner Wheels

Manner Wheels is a manufacturer of high-quality wheels and casters for various applications. The company was founded in 1960 and is based in Finland.

Manner Wheels offers a wide range of products, including heavy-duty wheels, casters, and material handling solutions for a variety of industries, including automotive, logistics, and healthcare. Their products are known for their durability, reliability, and performance, and they are used in demanding applications around the world.

14. Wicke USA

Wicke USA is a manufacturer of high-quality wheels and casters for various applications. The company was founded in 1931 and is based in North Carolina, USA.

Wicke USA offers a wide range of products, including heavy-duty wheels, casters, and material handling solutions for a variety of industries, including automotive, logistics, and healthcare. Their products are known for their durability, reliability, and performance, and they are used in demanding applications around the world.

15. Flexello Casters Inc.

Flexello Casters Inc. is a manufacturer of high-quality casters and wheels for various applications. The company was founded in 1972 and is based in Illinois, USA.

Flexello Casters offers a wide range of products, including light-duty and heavy-duty casters, and specialty casters for various industries, including aerospace, automotive, and material handling. Their products are known for their durability, reliability, and performance, and they are used in demanding applications around the world.

New Trends and Opportunities in the Caster Industry

1. Industry Demand Development Increases Demand for Casters

The global economic recovery is expected to increase the demand for casters in various industries in the next few years. According to market research, the caster market is projected to grow at a compound annual growth rate (CAGR) of around 1.9% between 2021 and 2026. This growth is being driven by several factors, including:

① Increased demand for material handling equipment

As the global economy continues to recover from the impact of the COVID-19 pandemic, there is likely to be an increase in demand for material-handling equipment. Casters are an essential component of these types of equipment, and their increased use is expected to drive growth in the caster market.

② Growth in e-commerce

The e-commerce industry has been growing rapidly in recent years, and this trend is expected to continue in the coming years. As more consumers turn to online shopping, there is likely to be an increase in demand for warehouse and logistics equipment, including casters.

③ Expansion of healthcare and hospitality industries

The healthcare and hospitality industries are expected to grow in the coming years as the global population continues to age and travel resumes post-pandemic. These industries rely heavily on casters for the movement of equipment and supplies, and their expansion is expected to drive growth in the caster market.

④ Infrastructure development

Global infrastructure development is expected to grow in the coming years as governments around the world invest in new projects to stimulate economic growth. These projects often require heavy equipment that relies on casters, and their expansion is expected to increase demand for casters.

⑤ Industrial Automation Industry

With the continuous advancement of industrial automation and intelligent manufacturing, casters have also begun to develop in the direction of intelligence and automation. For example, some mobile robots, automated warehouses, and other equipment have begun to widely use AGV casters to achieve functions such as movement and positioning. The demand in the AGV field will be a new track for the caster industry.

The increase in demand for casters in industrial automation and intelligent manufacturing is supported by data from market research. According to a report by Research and Markets, the global market for industrial casters is expected to grow at a CAGR of 5.2% between 2021 and 2028, driven in part by the increased demand from the automation and manufacturing industries.

In conclusion, the global economic recovery is expected to increase the demand for casters in various industries. The growth is driven by factors such as increased demand for material handling equipment, growth in e-commerce, expansion of healthcare and hospitality industries, and infrastructure development. These trends are expected to drive growth in the caster market in the coming years, supporting the projected CAGR of around 3%~4% between 2021 and 2026.

2. Caster Opportunities Brought by Global Industrial Transfer

Global industrial transfer, especially the transfer of manufacturing industries to emerging countries such as Vietnam, Mexico, the Philippines, Malaysia, India, and other countries, presents a significant opportunity for increased demand for casters. As companies relocate their manufacturing operations to these countries, there is an increasing need for equipment that can be easily moved around the factory floor.

In recent years, there has been a trend of manufacturers moving their production operations to emerging countries to take advantage of lower labor costs and favorable government policies. For example, many companies have relocated their manufacturing operations to countries such as Vietnam, where the labor cost is lower than in China. As a result, the demand for casters in these countries is expected to grow rapidly.

According to a report by Grand View Research, the Asia-Pacific region is expected to be the fastest-growing market for casters between 2021 and 2028, driven by the increasing demand from emerging countries such as India and Southeast Asian countries. In addition, the report suggests that the growth in demand for casters in these regions is also driven by the increasing adoption of automation and material-handling equipment.

The industrial transfer to emerging countries is not only driving the growth of the caster market but also presents an opportunity for manufacturers to expand their businesses in these regions. As manufacturing operations continue to expand in emerging countries, there will be an increasing need for specialized caster products to meet the unique needs of these industries. Manufacturers who can provide high-quality, customized products will have a significant advantage in these markets. In conclusion, the industrial transfer to emerging countries presents a significant opportunity for increased demand for casters.

The growth of the caster market in these regions is driven by the increasing demand from manufacturing industries and the adoption of automation and material handling equipment. Manufacturers who can provide specialized products to meet the unique needs of these industries will have a significant advantage in these markets.

3. Trends in Casters’ Material and Technology Upgrades

From the perspective of technology upgrading, the caster industry is adopting new technologies to improve the performance and functionality of caster products. One example of this is the use of smart technology in caster products. Smart casters are designed to provide real-time data on the movement, location, and condition of the equipment. This data can be used to optimize the performance of equipment, improve safety, and reduce downtime. For example, Colson Group USA has recently introduced a new line of smart casters that use sensors and wireless communication technology to provide real-time data on the movement and condition of the equipment.

Another example of technology upgrading is the use of automation in caster production. Automation can help to increase production efficiency, reduce costs, and improve product quality. For example, Hamilton Caster has recently invested in a new automated production line that uses robotics and other advanced technologies to produce high-quality caster products more efficiently.

From the perspective of material upgrading, the caster industry is adopting new materials to improve the durability, strength, and performance of caster products. One example of this is the use of advanced polymers in caster wheels. Advanced polymers can provide superior performance in terms of load capacity, shock absorption, and wear resistance. For example, Tente has recently introduced a new line of casters that use advanced polymers in the wheels to provide superior performance in a variety of industrial applications.

Another example of material upgrading is the use of lightweight materials in caster products. Lightweight materials can help to reduce the weight of equipment and make it easier to move around. For example, Bullcaster has recently introduced a new line of casters that use lightweight materials such as aluminum and nylon to provide high load capacity while reducing the weight of the equipment.

Summary of the Caster Industry and Market

The caster industry is an important part of the global economy and is characterized by a wide range of SKUs and a high degree of customization. Major suppliers are concentrated in China, and the industry is expected to experience significant growth in emerging markets such as Southeast Asia and India.

The industry is currently undergoing a rapid transformation driven by technology and material upgrading. This transformation is seen in the use of smart technology and automation to improve the performance and functionality of caster products. Manufacturers are also adopting advanced polymers and lightweight materials to improve the durability, strength, and performance of caster products.

The demand for casters is expected to increase in the coming years, driven by factors such as the global economic recovery, the trend towards industrial automation and intelligent manufacturing, and the transfer of manufacturing industries to emerging countries.

Overall, As the global economy recovers and new manufacturing centers emerge, the demand for casters is expected to continue to grow, driven by advances in technology and a focus on improving performance and functionality.

If you are thinking about entering the caster industry, or you are looking for a high-quality caster supplier, please contact Bullcaster without any hesitation, we can provide you with high-quality casters at the best price.