I. The Choice of Medical Casters Is Very Important

In this issue, let’s talk with you about how to choose medical casters. Don’t know what a caster is? Or do you feel a little far away from our lives? Let’s take a look at the picture below first

You might be familiar with the images above, which include a supermarket shopping cart, an office chair, and an airport luggage cart. They all share a common feature: wheels at the bottom, similar to the position of human feet, likely giving rise to the name ‘casters’. Many supermarket carts are hard to push, or they spin around their fixed axis, making it difficult to move in a straight line — a clear sign of caster problems.

While the inconvenience of a hard-to-push shopping cart is minor and easily resolved by switching to a better one, the stakes are much higher with medical equipment. For instance, if the casters of an IV stand, dialysis machine, or hospital bed fail, resulting in detachment, cracking, or sudden stops, the entire device could topple, causing damage and potentially injuring people. Patients on a bed could fall and suffer secondary injuries, leading to dire consequences. Therefore, choosing the right casters is crucial.

II. Why You Need to Use Casters?

Casters are wheels installed at the bottom of furniture to facilitate easy movement. Setting aside their specific applications, their primary purpose is clear — to make movement convenient.

In equipment that needs to be mobile, it’s simply a matter of designing mounting holes and attaching ready-made wheels — this is the case for the vast majority of medical equipment products. These wheels are what we typically understand as casters. Casters apply to a wide range of items, including medical devices, high-tech equipment, kitchen appliances, laboratory equipment, general equipment, and airport trolleys.

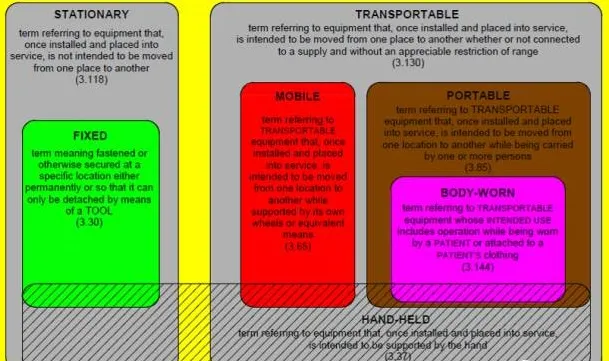

For medical devices, according to the International Electrotechnical Commission (IEC) standard IEC60601-1, which covers the basic safety and essential performance of medical electrical equipment, medical devices can be categorized into several types. Transportable and mobile sub-categories particularly require casters for movement. Even some medical devices categorized as fixed due to their heavy weight, such as CT scanners and MRI machines, often need wheels during installation for ease of movement. This demonstrates the broad applicability of casters.

The following image illustrates a variety of common mobile medical equipment, ranging from IV stands for fluid administration, to dialysis machines, ventilators, anesthesia machines, minimally invasive surgical carts, ultrasound diagnostic machines, hospital beds, and more. If you’ve visited a hospital, you’re likely familiar with casters.

III. How to Choose Casters for Medical Equipment

1. Understand the Classification of Casters

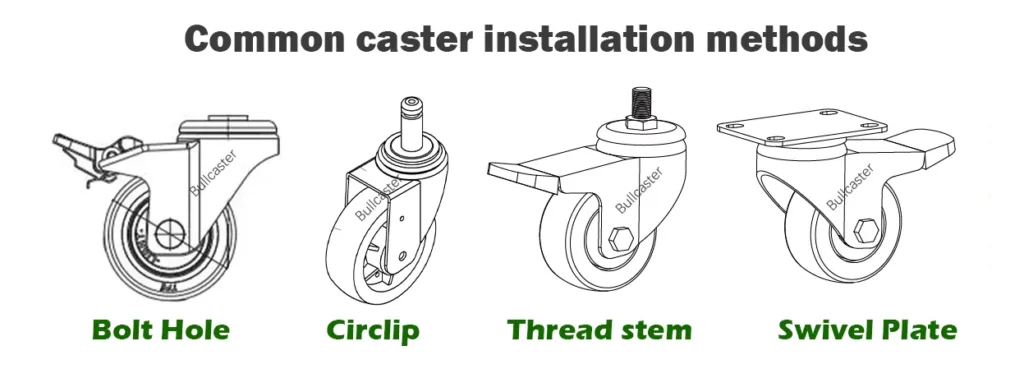

In the previously mentioned image, we already touched upon the classification of casters, applicable in various contexts like medical devices, high-tech equipment, kitchen appliances, laboratory equipment, general equipment, and airport trolleys. Different caster manufacturers have their categorizations based on material, installation method, load capacity, application, etc. For more detailed classifications, refer to our articles on caster types.

When selecting casters for medical equipment, medical-specific casters are often the first choice. The main difference between medical and non-medical casters lies in their suitability for common cleaning and disinfection agents, enhanced safety, higher reliability, and lower rolling and swivel resistance. Specific subfields may have their standards, like ANSI ICWM: 2012 and EN12531, which won’t be elaborated here. However, this doesn’t mean non-medical casters can’t be used in medical devices. The classification isn’t absolute, and the line between medical and non-medical is not always clear-cut. Sometimes, it’s just a matter of certification. Manufacturers’ categorizations are subject to change, and designers often balance safety, clinical requirements, practical use, and cost. As long as they meet relevant standards and requirements, non-medical casters can be used in medical devices.

The choice of casters should also consider the usage environment. Generally, the environment for medical devices is not as harsh as industrial settings, as hospitals have specific requirements for temperature, humidity, cleanliness, etc. However, if the anticipated use is in special environments like high temperature and humidity, or extreme cold, then casters suitable for those conditions should be selected based on the manufacturer’s specifications.

In short, as long as the casters are safe, meet standards and requirements, and are reasonably priced, they are suitable for use!

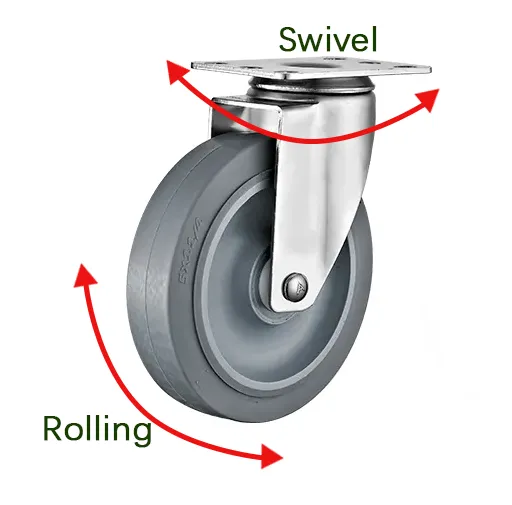

2. Caster Wheels Control

Generally, casters have two degrees of freedom: swivel and rolling. Swiveling is like the caster’s “self-rotation,” enabling steering. This swivel axis is usually fixed to the equipment. Some casters are non-swivel and can only roll forwards and backward; however, rolling is a feature of all casters. It is through rolling that the casters enable the equipment to move forward and backward.

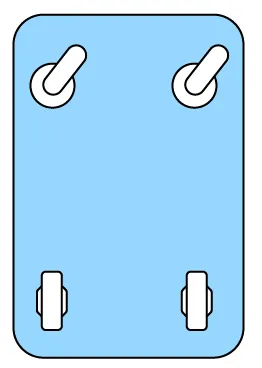

Currently, the control of casters is primarily mechanical, similar to bicycle brakes and the mechanical handbrake in a car. Depending on the control method, it can be divided into individual control and central control. Individual control is relatively straightforward: each caster needs to be locked and unlocked separately. As illustrated in the image on the left, each caster needs to be locked to secure the entire device, though some products may only require locking two casters. Central control, like the ultrasound diagnostic equipment shown on the right, involves locking the entire device by stepping on a central pedal, indicated by the arrow. This method is more common in medical devices that require rapid activation or locking, or in cases where individual control is difficult due to the structure.

The choice of control method is often determined by market demand and the product itself. Designers select the appropriate solution based on these requirements.

For individually controlled casters, there are two types of control mechanisms: simultaneous locking of swivel and rolling (referred to as TB, The Locking Brake), and locking of just the swivel (DB, Directional Locking Brake, in the image below). The advantage of locking only the swivel is that no matter how the equipment is pushed, it can be made to move only in one direction, either forward or backward.

3. Caster Load Capacity

The formula for calculating the load capacity of a caster is as follows:

T=(E+Z)*N/M (Use the online caster load calculator)

Where:

- ( T ) = Required load capacity per wheel or caster;

- ( E ) = Weight of the transport equipment itself;

- ( Z ) = Maximum load weight;

- ( M ) = Number of wheels and casters used;

(Factors such as position and uneven weight distribution should be considered); - ( N ) = Safety factor (approximately 1.2 – 1.5).

To put it simply, the calculation involves dividing the maximum load by the minimum number of casters and then multiplying by a safety factor. For example, suppose the individually controlled mobile device shown earlier has a self-weight of 80kg ((E)) and can carry a person weighing up to 150kg ((Z)). The maximum load capacity for the casters would then be 230kg ((E + Z)). Considering that in extreme conditions only 3 of the 4 casters might be in contact with the ground ((M)), and such situations usually don’t require a very high safety factor, a factor of 1.2 would suffice. Thus, the result for (T) would be 92kg ((T)). This result can be used to select appropriate casters based on the manufacturer’s specifications. Additionally, it’s important to note that caster manufacturers differentiate between static and dynamic loads, and the selection should be based on the intended use and expected conditions of use.

4. Caster Wheel Size

Indeed, the result of the load calculation is a crucial input for determining the size of the caster, as larger diameters can support greater maximum loads. Common caster sizes include 75mm, 100mm, 125mm, 150mm, and 200mm. Generally, the larger the caster, the greater its load capacity. Larger casters enhance the equipment’s ability to overcome obstacles, improve maneuverability, and require less pushing effort. However, larger casters also raise the center of gravity of the entire apparatus, potentially decreasing its stability. Additionally, the cost of the caster increases with size. Therefore, it’s important to strike a balance by considering all these factors.

5. Caster‘s Mounting Types

The installation of casters primarily depends on the type of control required, whether it’s central or individual control. Based on different needs, the appropriate type of caster should be chosen. If central control is needed, I recommend prioritizing solutions from established manufacturers, as their mature solutions have often been market-tested. If these are not suitable, designers can create their central control systems, such as a brake mechanism that can be raised and lowered for better grip.

For individual control, there is generally more flexibility in choice, such as common screw mounting and plate mounting. Screw mounting is typically suited for small-sized installation surfaces, while plate mounting is better for heavy loads. Designers can decide based on their preferences. However, it’s important to consider thread loosening prevention for any threaded connections. Otherwise, caster detachment could lead to disastrous consequences.

6. Wheel Materials

Caster materials mainly include supersynthetic rubber, polyurethane, plastic, nylon, steel, high-temperature resistant materials, rubber, and S-type synthetic materials. Many designers, often coming from mechanical and related fields, may not be familiar with these materials. Therefore, the simplest method is to refer to the caster manufacturer’s specification sheets. Manufacturers usually list the different parameters of casters clearly, aiding engineers in selection. For information on how to choose caster material, refer to our previous guide.

Additionally, it’s worth mentioning that caster materials can vary in hardness. Generally, hard casters are suitable for hard, flat surfaces, as they produce less noise during movement and require less effort to push the equipment. Soft casters, on the other hand, are better suited for uneven surfaces or areas with debris like metal filings. They provide better protection and shock absorption for the equipment, although they may require more effort to push.

IV. Quality Testing of Casters

1. Standard Caster Test

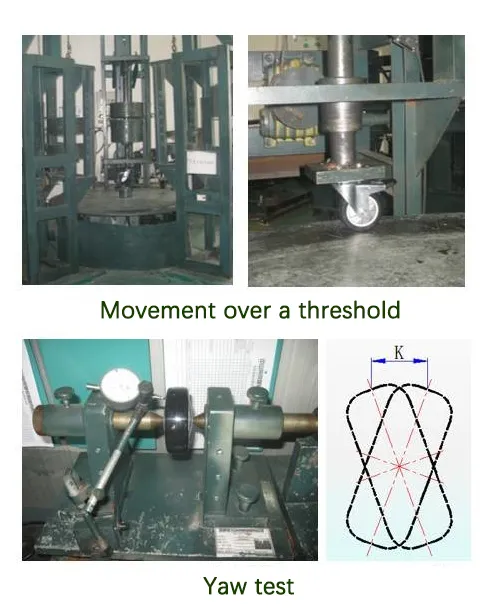

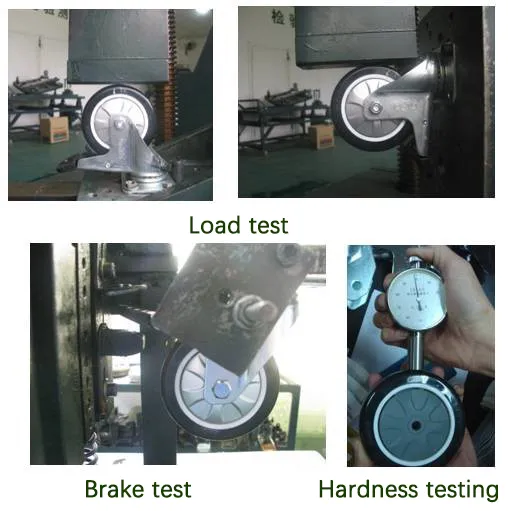

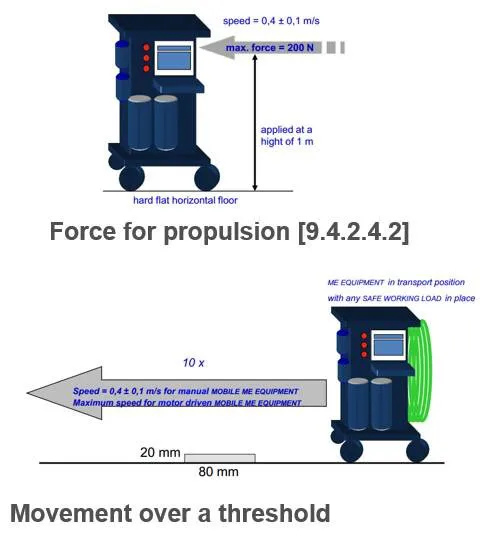

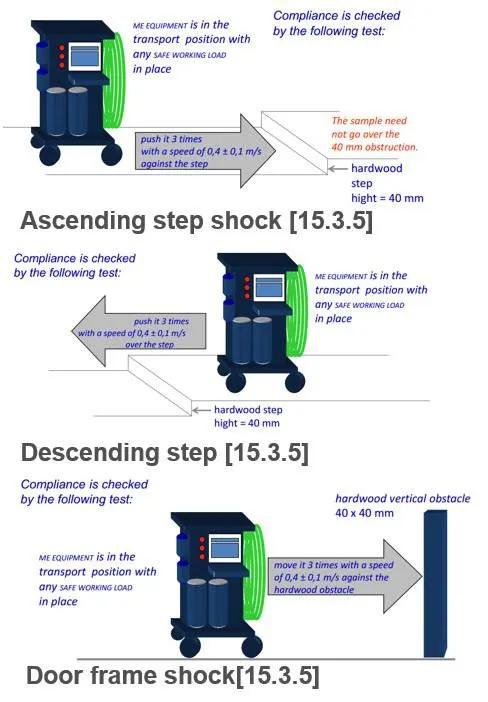

As previously mentioned, different industries have different standards for casters. Generally, caster manufacturers conduct various tests on their products according to industry standards. Some common tests, as shown in the following image, include load capacity, steps (typically around 5-6mm, differing from the IEC tests mentioned later), braking force, hardness, deflection tests, and more.

Designers can consult with manufacturers to see if these tests meet the design requirements for medical devices. If necessary, they can request manufacturers to conduct specific tests, provided that there is an agreement on the costs and time involved. Additionally, customizing casters is an option, with the most common customization being a color change. Of course, this too depends on mutual agreement regarding costs and expectations. Larger development companies with bigger order volumes have stronger negotiating power, whereas smaller companies might not receive as much attention.

2. Medical Device Testing

IEC60601-1 sets the basic safety and essential performance requirements for medical electrical equipment. It’s considered a general guideline for medical device requirements, and many countries base their national standards on it, such as China’s GB9706.1. For specific types of medical devices without dedicated standards, IEC60601-1 is often applicable. In the third edition of IEC60601-1, tests related to casters are covered under several sections. For ease of reference, I have included the specific chapters below, and those interested can consult the original standard for more details.

For equipment with a high center of gravity mentioned earlier, it will be difficult to pass the instability test (Instability). Although designers can use various methods to solve this problem, such as increasing the diameter of the chassis, special-shaped chassis, lowering the center of gravity, etc., it is best to evaluate it at the early stage of the design so that corresponding measures can be taken as early as possible.

A few words about the test of moving over a threshold, the elevator in the hospital cannot be completely flush with the floor when it stops, and there will be more or less steps. When going up the steps, will cause difficulties in moving medical equipment. After all, you cannot always rely on human hands to pull it. Therefore, 9.4.2.4.3 of the third edition of the standard has a new requirement. The original intention is that a small step (20mm) does not affect the passage of the equipment at normal speed (0.4 m/s), that is, the step can be successfully crossed without causing any risk. However, this requirement has brought huge design difficulties to various medical device companies, because it is difficult for equipment with caster diameters below 125mm to pass this test. Increasing casters will often lead to increased costs and instability of the entire equipment. So in version 3.1, perhaps after hearing widespread opinions that this requirement was too harsh, the IEC committee lowered the 20mm to 10mm and increased the passing speed from 0.4 m/s to 0.8 m/s, which finally allowed relevant manufacturers and designers to The reader breathed a sigh of relief. In addition, version 3.1 also has higher requirements for the thrust of the instrument, which will not be discussed in detail here.

The applicability of IEC in various countries will not be discussed here, but once applicable, the tests it stipulates are the minimum requirements for medical devices. Many medical device companies also need to conduct reliability testing or have more stringent corporate requirements, and different products may have different requirements due to different intended uses. Even if the test is passed, it does not mean that the risk is acceptable, and it often does not mean that the risk is acceptable. Risk management and FMEA (Failure Mode and Effects Analysis) are required for assessment and control.

V. Global Medical Caster Wheel Supplier

Bullcaster: Premier Medical Casters Supplier in China

We’re a renowned supplier of high-quality, cost-effective medical casters based in China. Our commitment to excellence and customer satisfaction has established us as a trusted partner in the global healthcare industry.

we specialize in a wide range of medical casters, designed to meet the dynamic needs of medical environments. We supply more than 200,000 cost-effective medical casters to users around the world every year.

VI. Conclusion

Here are some of my views on medical casters. If you find any topic interesting, feel free to leave a comment for discussion.

- Wheels are a great invention that enables the easy transportation of heavy objects. They are cost-effective, widely applicable, reliable, easy to maintain, efficient, and do not require electric power. They will continue to be a part of our lives for a long time.

- For central control designs, prioritize using the manufacturer’s interface solutions, and resort to custom designs only if necessary.

- Consider lowering the center of gravity, increasing the chassis diameter, or using unconventional chassis shapes to enhance stability.

- If a medical device does not have high requirements for mobility and stability, the price of the casters becomes a key factor.

- It’s advisable to choose reliable products from well-known brands, using cheaper casters only when they meet the requirements.

- Casters can significantly affect user experience (in terms of rotation, and rolling), and failure (loosening, breakage, brake malfunction) can have serious consequences and should not be taken lightly.

- For medical devices, casters are not a selling point and are difficult to mark up in price. Ensure safety, reliability, and usability without excessively investing in their development.

Bullcaster is an experienced medical caster manufacturer, we can provide you with a full range of medical casters and custom casters. For any of your caster needs, we are always available to provide you with consultation and quotations, contact us today!